Tesla Model Y, One Maverick Metal at a Time

Paradox of the Energy Transition, Powered by Cutting-Edge Metals.

By Gaia Research Team.

The Gaia Research Team specializes in sustainable mining investments, focusing on responsible resource extraction. Committed to transparency and innovation, the Team aims to transform the mining sector into a more sustainable industry that benefits both the economy and the planet while addressing the huge supply and demand gap for critical minerals.

A Metal Machine for a Greener Tomorrow

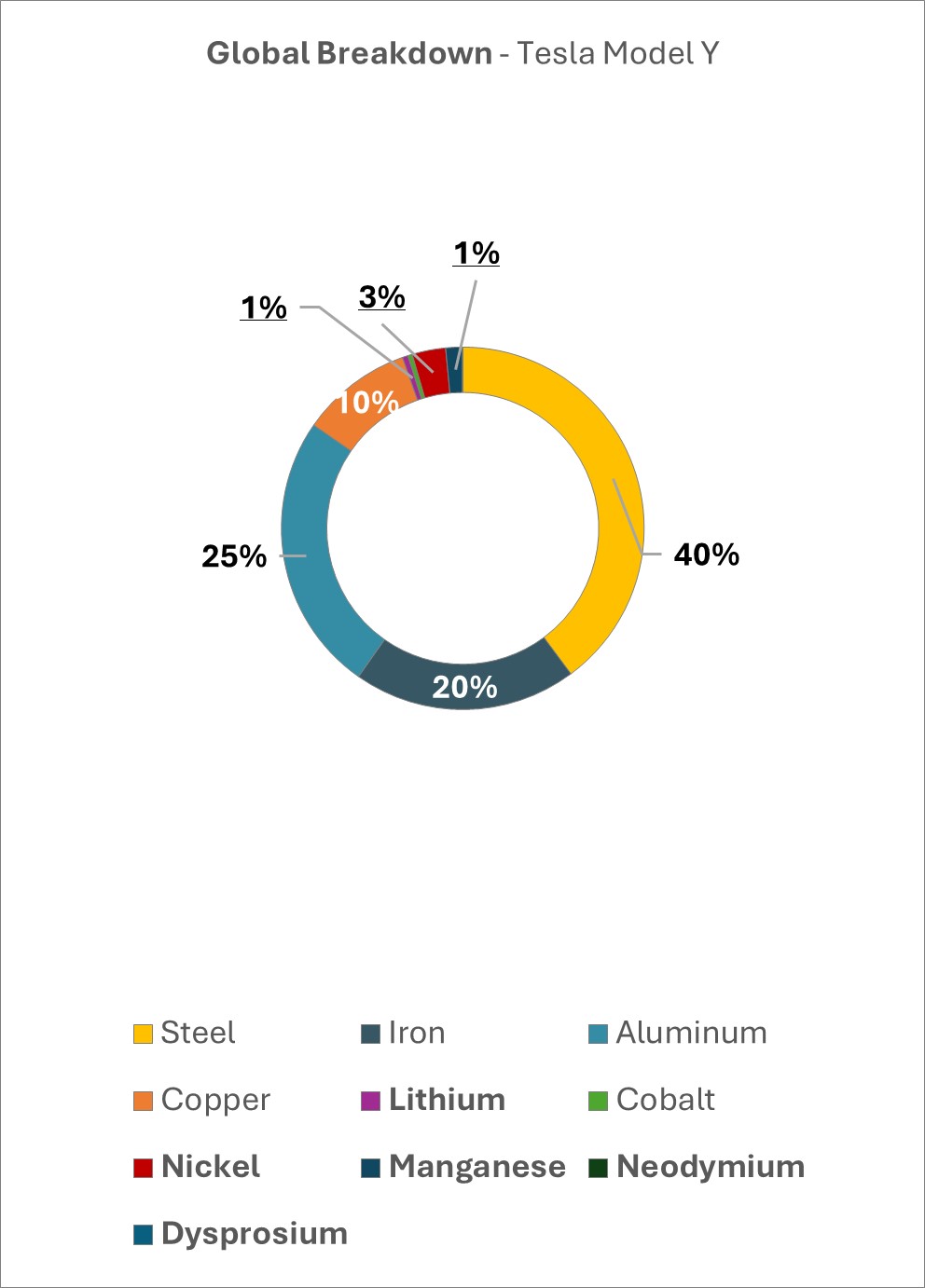

The Tesla Model Y, a flagship electric vehicle (EV), is an engineering marvel designed to lead the “burden” toward a sustainable future. Beneath its sleek aluminum chassis lies a complex web of materials sourced from every corner of the globe. From ferrous metals like steel and iron to non-ferrous components such as aluminum and copper, Model Y represents the confluence of innovation and natural resource dependency.

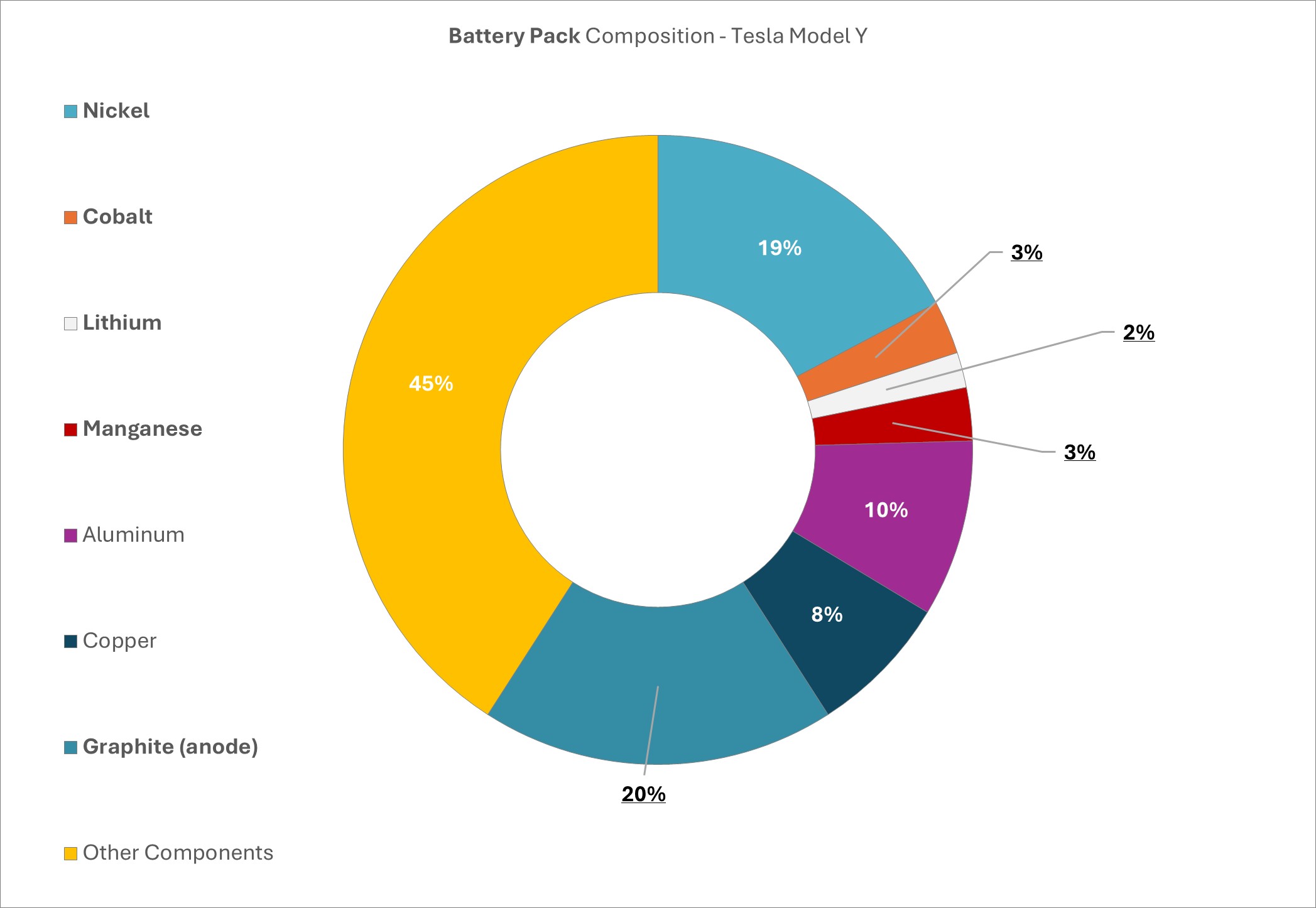

At the heart of the Model Y is its battery pack, a technological cornerstone in EV design. Weighing approximately 480–550 kilograms, the battery relies heavily on critical metals: nickel, cobalt, lithium, and manganese. Together, these materials account for 25% of the battery’s total weight. Nickel, prized for its energy density, dominates the mix at 15–20%, while cobalt and manganese contribute up to 3% each, ensuring stability and longevity.

The car’s motors add another layer of complexity. Tesla’s permanent magnet synchronous motors rely on rare earth elements like neodymium and dysprosium, essential for producing the strong magnetic fields that power the vehicle. These metals, while used in small quantities, represent a significant supply chain challenge due to their geographic concentration.

The Global Mining Chain Behind Tesla

To understand Tesla Model Y, one must first traverse its supply chain, a journey spanning continents and industries.

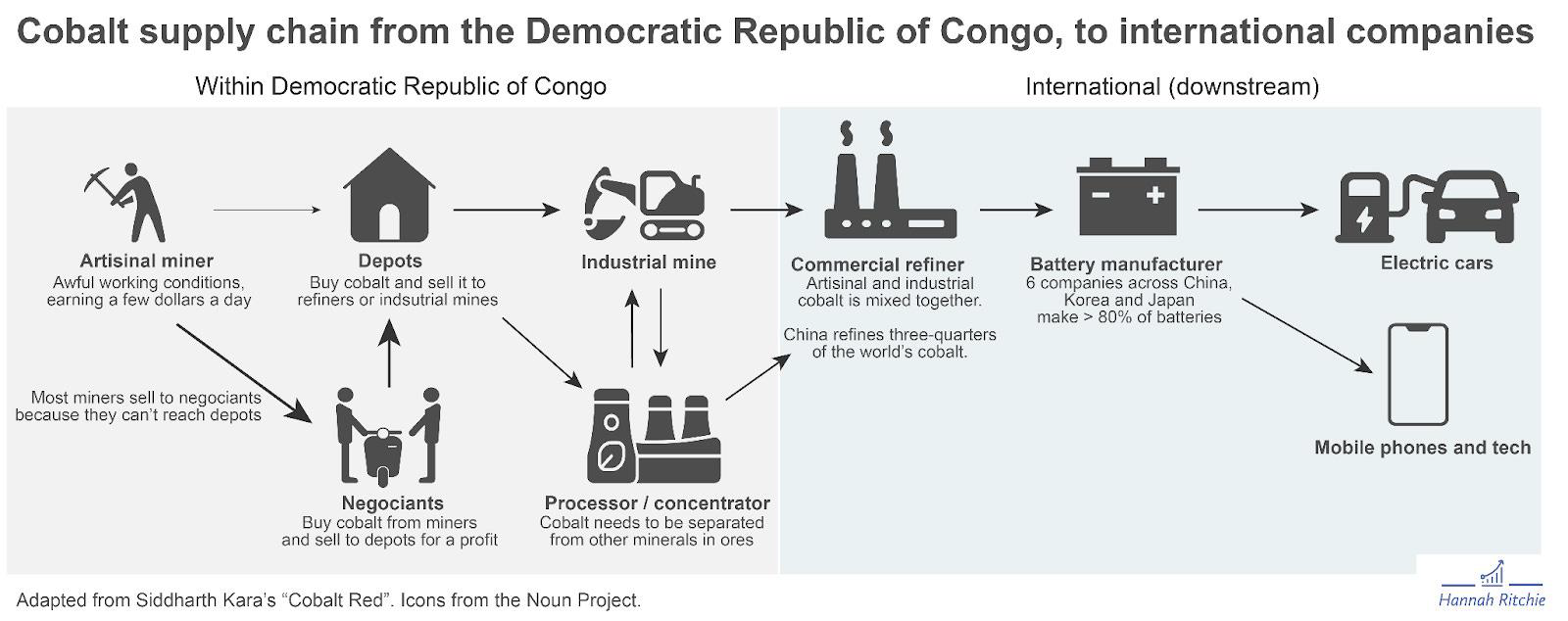

Exploration: The story begins with geological surveys and satellite imagery that pinpoint deposits of lithium in Chile’s Atacama Desert, cobalt in the forests of the Democratic Republic of Congo (DRC), and nickel in Indonesia’s rainforests.

Extraction: Open-pit and underground mining operations bring these materials to the surface. For instance, the DRC supplies nearly 70% of the world’s cobalt, while Australia leads lithium production with its hard rock spodumene mines.

Refining and Processing: Once mined, raw materials often make their way to processing hubs like China, which dominates global rare earth refining with a 90% market share. Nickel ores from Indonesia are transformed into battery-grade material in high-emission smelters.

Transport and Manufacturing: These refined components are shipped to Tesla Gigafactories in Nevada, Berlin, and Shanghai, where they are assembled into battery packs and integrated into the Model Y.

The Hidden Costs of an Electric Revolution

The rest of this article is reserved for signed-in users.

Sign in or create your free account to read the full article.

Comments (0)

Sign in or create a free account to leave a comment.